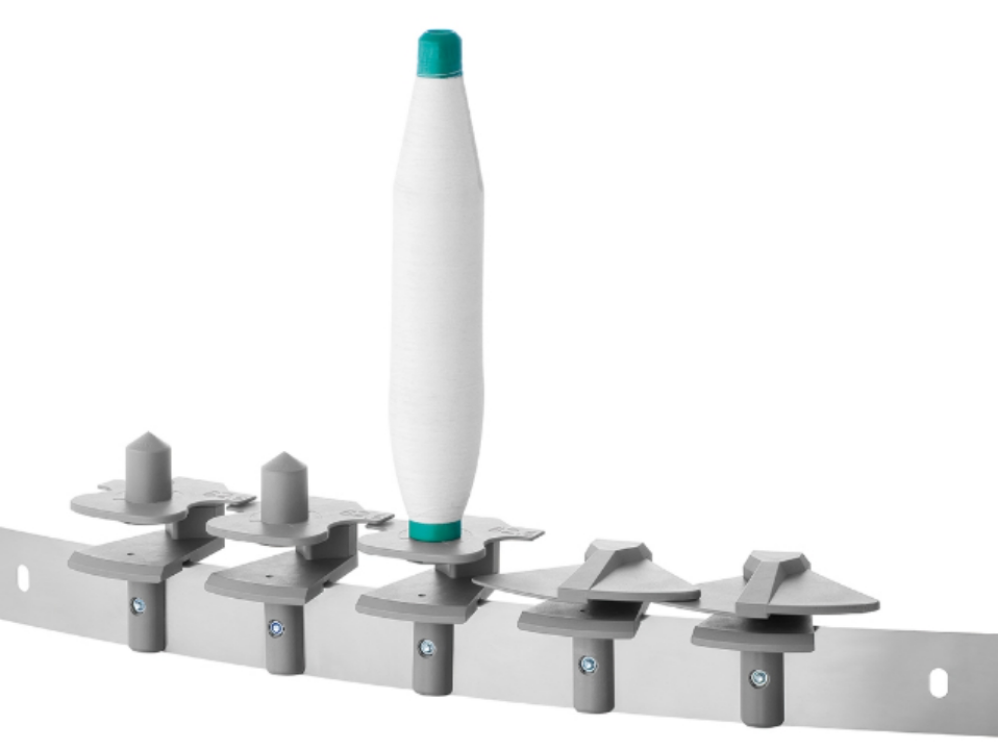

Bobbin Smart Ream

The empties for auto doffer machines are held on the spindles either by spring buttons or clutch. Incase of clutch system, the buttons move out by centrifugal forces created by rotation.

But over a period of time, due to the following reasons, grooves are formed inside the empties near the button area.

As the grooving affects the fitment and seating, there is an increase in doffing time and loss of production time and thus efficiency.

Bobbin Smart Ream

Laufer provides a fruitful solution for tight cops issue with less time and effortless system, the button seating area of the cops is cleaned by reamer to enable smooth pressing and thus helps in smooth doffing of cops.

- Ring frame doffer application

- Spinning application

| Bobbin Application | Ring machine |

|---|---|

| Bobbin Height | 180 - 210MM |

| Bobbin Angle/ Type | 1:40 & 1:64 |

| Bobbin base inner diameter | 18/20MM |

| 230 Bobbin height | On Order* |

| Bobbin Material | Poly Carbonate, Poly Propylene & Polyethylene |

| Bobbin tray storage capacity | 300 Nos |

| Cycle time | 20 Sec / Bobbin |

| Operations | PLC - Delta |

| Make of display | Delta - Taiwan |

| Make of reamer motor | ABB - US |

| Make of Pneumatics | Janatics - India |

| Power Consumption | 1 Units/3hrs |

| Air Consumption | 0.02 CFM |

| Bobbin Loading | Manual |

| Bobbin Collection | Manual |

- First automatic reaming machine by avoiding free hand

- ROI with in 6 months.(Approx.)

- PLC controlled process.

- Plug and play machine.

- Less maintenance.

- Less power & air consumption with proven Kaizen rule.

- 80 sec/doff time reduction immediately.

- Increase in productivity up to 5 Kg /machine for a day.

- Ring machine doffer components life increased upto 12 month.

- Bobbin life increased upto twice the time after using reaming process.

Download Corporate Brochure

You can download corporate brochure here